Home > Energy

Energy

Quick links:

Accelerating the energy transition with artificial intelligence

At Probayes, we help our customers make their buildings and processes more energy efficient.

Probayes uses a number of tools to address energy-related challenges:

- Accelerating R&D to speed up time to market for new technologies and creating digital twins to predict wear and plan maintenance

- Optimizing renewable energy to help producers select the optimal location for their facilities, improve grid integration, and manage smart grids

- Bringing new technologies to renewable energy to forecast production, secure the energy supply, and boost the proportion of renewables in the energy mix

- Reducing energy consumption through smart energy-management solutions for buildings and industrial processes

Algorithms tailored to the energy industry

Probayes develops, tests, and implements a wide range of algorithmic tools on energy-related use cases in many industries. Our core approaches to energy-related projects include:

Operational research and combinatorial optimization

- Transportation network optimization (logistics and distribution, public transportation, delivery routes, etc.) to shorten the distances covered

- Right-sizing inventory and optimizing how inventory is organized in space to reduce the amount of space required and the associated costs

- Geometrical optimization to locate waste so as to reduce the number of vehicles required to remove it

- Self-consumption optimization

Time-series processing

- Detecting IoT data anomalies to optimize the quantity and quality of input data

- Predictive maintenance solutions to reduce costs and extend equipment lifespans

Time-series processing and prediction

- Predicting solar panel production

La Operational research combined with time-series processing and prediction

- Building energy management and optimization

Computer vision applied to thermography

- Leak detection on heat networks

- Scanning building facades to detect heat loss

Better results, together

We work hand in hand with your business experts

Regardless of your industry, energy-related projects are usually particularly complex, with a large number of data sources. At Probayes, we work hand in hand with our customers’ experts to understand the many moving parts of the challenge at hand so that we can develop the best possible solution. We make communication a priority to ensure that we learn from each other throughout the project. Our customers come away with a better understanding of AI implementation in energy-related scenarios, and our people acquire a deep understanding of the issues our customers face. Each project strengthens our long-lasting customer relationships.

Success stories

Renewable energy production forecasting

Project to predict solar panel energy production

Batisense

Energy optimization solution for buildings

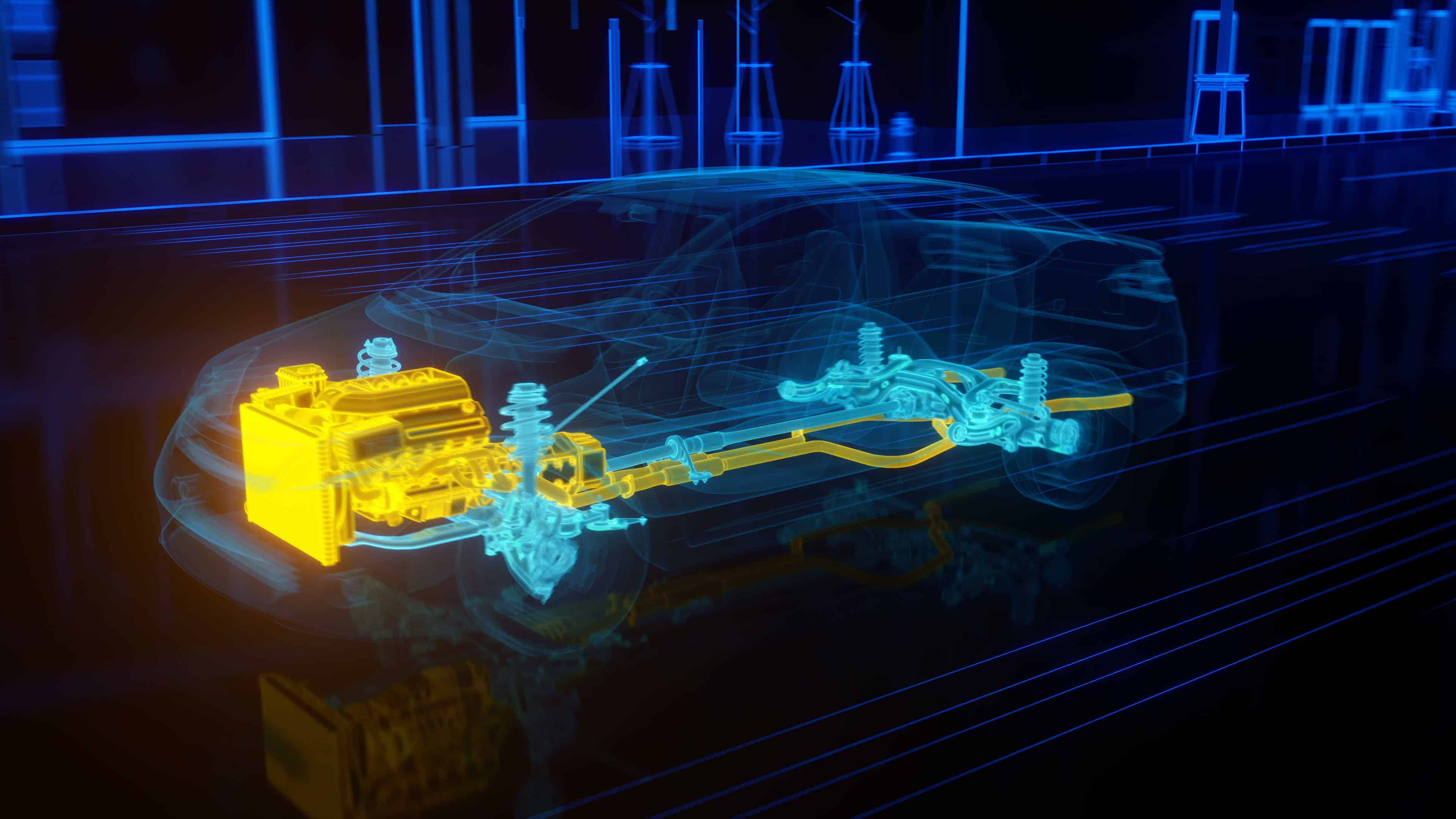

Making hybrid vehicle engines more efficient

Project to optimize the energy consumption of a hybrid engine

Self-consumption optimization

Project allowing …

EasymAInt predictive maintenance solution

With EasymAInt, makes predictive maintenance simple. Just install plug-and-play sensors to monitor your data and equipment and you are ready to go!

Optimnet

Optimnet is custom decision-assistance tool that adapts to your unique logistics system optimization needs.

Eramet

Success story

Eramet is one of the world’s leading metal alloy producers. The Eramet plant in Knivesdal, Norway, produces silicomanganese alloys.

Challenge

When manufacturing processes are optimized, premium raw materials can be replaced with less-expensive alternatives without affecting product quality. Eramet turned to Probayes for a real-time solution capable of detecting exactly when to switch out the more expensive raw material for the cheaper one and of generating recommendations for when to switch back in the event of drift.

The project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam sed leo quis lectus ultricies blandit nec sit amet urna. Integer mi ligula, tempor eget dapibus id, posuere vestibulum est. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.

Results

reeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeqtg

“Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce eu lacus diam. Cras congue, neque ac mattis efficitur, nibh ipsum fringilla nunc, sed iaculis neque odio non orci. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Praesent lacinia, urna quis rhoncus lobortis, urna neque tempus tellus, quis auctor justo lectus vitae libero. Nulla non porta odio. Donec diam est, varius id ullamcorper a, efficitur nec libero”

First name Last name

Position – Company

Framatome

Success story

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam sed leo quis lectus ultricies blandit nec sit amet urna. Integer mi ligula, tempor eget dapibus id, posuere vestibulum est. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.

Challenge

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam sed leo quis lectus ultricies blandit nec sit amet urna. Integer mi ligula, tempor eget dapibus id, posuere vestibulum est. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.

The project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam sed leo quis lectus ultricies blandit nec sit amet urna. Integer mi ligula, tempor eget dapibus id, posuere vestibulum est. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.

Results

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam sed leo quis lectus ultricies blandit nec sit amet urna. Integer mi ligula, tempor eget dapibus id, posuere vestibulum est. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce eu lacus diam. Cras congue, neque ac mattis efficitur, nibh ipsum fringilla nunc, sed iaculis neque odio non orci. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Praesent lacinia, urna quis rhoncus lobortis, urna neque tempus tellus, quis auctor justo lectus vitae libero. Nulla non porta odio. Donec diam est, varius id ullamcorper a, efficitur nec libero”

First name Last name

Position – Company

Our customers*

*We take confidentiality seriously. Some of our customers’ names and other identifying information have been removed.

Copyright 2019 – Probayes – 53 avenue Kuntzmann – 38330 Montbonnot – France – Tel: +334 76 42 64